Shokunin Kishitsu - The Craftsman's Spirit

At O&B, we live by the spirit of Shokunin Kishitsu – the craftsman’s spirit. Through relentless iteration and refinement, we strive for perfection in every detail.

Each design iteration we make surpasses its predecessor, driven by our passion for flawless music reproduction. We meticulously select each component, hand-solder every connection, and carefully twist every wire. Our skilled artisans pour their heart and soul into every product, fueled by an unyielding pride in their craftsmanship.

Drawing on over 15 years of experience, we combine this passion for sound with time-honored engineering principles to craft amplifiers to elevate your audio experience. We believe that true audio excellence is found in the smallest details, which is why we rigorously engineer each amplifier to provide optimal performance.

Our Design Philosophy

Our amplifier designs are built on a foundation of a wire with gain. We additionally ensure performance, reliability, and precision. Every element is carefully engineered to ensure clean, stable audio, even under demanding conditions. Here’s how we approach the key areas:

1. Signal Integrity and Precision

- High CMRR (Common-Mode Rejection Ratio): We use matched passive components and laser-trimmed resistors to maximize CMRR and minimize common-mode interference.

- Low THD+N (Total Harmonic Distortion + Noise): Premium components and capacitors are selected to keep distortion and noise in the input section at minimal levels, preserving sound quality.

- Improved PSRR (Power Supply Rejection Ratio): Cascaded filters are integrated to reduce power supply ripple and noise, ensuring a stable input stage.

- Effective RFI Mitigation: We choose filters and ferrites to minimize radio-frequency interference (RFI) without degrading the 20 Hz to 20 kHz signal range.

- Optimized Signal Integrity: Advanced PCB design and strict routing rules maintain signal fidelity and prevent degradation across the amplification process.

- High SNR (Signal-to-Noise Ratio): Specialized PCB designs and feedback systems help achieve a high SNR for clear, undistorted audio.

- Minimized Signal Coupling and Cross-talk: A careful PCB layout reduces signal coupling and cross-talk, ensuring each channel operates independently.

- Precise Gain Matching: We use high-precision components to match the gain between channels accurately, ensuring balanced output.

2. Power Supply and Thermal Management

Our power supply and thermal systems are designed to deliver consistent performance while preventing thermal issues.

- Advanced Thermal Protection: Heatsinks and thermal protection ensure active components stay within safe operating temperatures, even under heavy loads.

- High-Performance Bulk Capacitors: Bulk capacitors with high ripple current ratings ensure steady power delivery, reducing voltage sag and ripple.

- Dual Shielded Toroidal Transformer: The oversized, dual-shielded transformer delivers clean power even under heavy loads. / Even under heavy loads, the oversized, dual-shield transformer delivers clean power.

- Low-Noise Linear Regulators: High PSRR linear regulators ensure that auxiliary functions and control circuitry receive clean power, minimizing noise.

- Accurate Star Grounding: A well-designed star grounding system reduces internal ground loops. This ensures optimal signal integrity is maintained.

- Ultra-Low Noise Input Section: A dedicated low-noise section minimizes hum and noise, preserving audio quality from the start.

3. Overload Protection and Power Management

Instead of using traditional VI limiters, which compress sound quality, our amplifiers feature a current monitoring system. This ensures that performance remains uninterrupted, even under extreme conditions, and avoids limiting dynamic range.

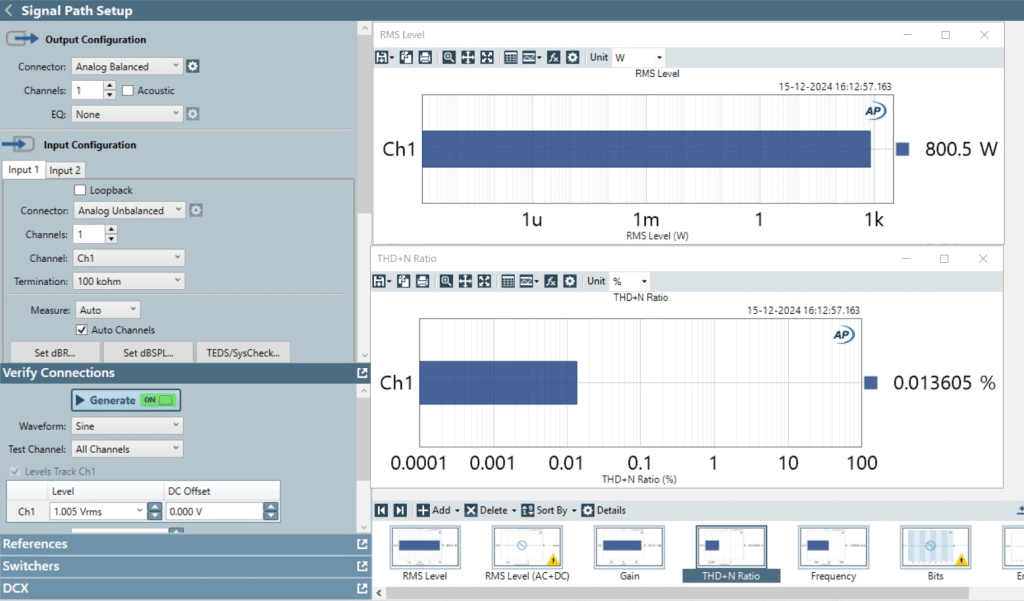

4. Conservative Power Rating

Our power ratings are conservative and reflect the amplifier’s sustained performance. We can push peak power up to 1.2 to 1.3 times the rated output for a sustained period of time, maintaining stable operation even during intense demands.

5. Unrestricted Output Current

Our amplifiers are designed to deliver significant output current, easily handling demanding speaker loads. For example, the HCA300 provides 35A, and the HCA500 delivers 46A, ensuring full control over speakers with high current requirements.

6. VBE Matching and Thermal Bonding

We precisely match the (VBE) of BJTs to reduce offset voltages and thermal drift. Thermal bonding techniques are also used to ensure that temperature variations are consistently tracked for stable performance.

7. Beta and Tolerance Matching

We beta-match BJTs in the Voltage Amplifier Stage (VAS) to maintain consistent current gain and minimize distortion. Additionally, tolerance matching ensures that the gain chain performs predictably across different units.

8. Output Stage Decoupling and Beta Matching

In the output stage, we decouple each BJT to minimize parasitic inductance, improving performance. Beta matching ensures balanced current sharing, which reduces distortion and ensures stability.

9. Precision-Engineered for High Ambient Conditions

We design and build our amplifiers with an emphasis on durability and thermal resilience, particularly for the demanding environmental conditions prevalent in regions like India. To address the extreme temperatures, all key components—such as heatsinks and toroidal transformers—are intentionally oversized. This ensures that the amplifier’s thermal management system can efficiently dissipate heat and maintain stable operation, even under high ambient temperatures. The oversized heatsinks provide enhanced surface area for better heat dissipation, while the toroidal transformers are rated to handle higher thermal loads, ensuring clean and reliable power delivery despite sustained high temperatures. This deliberate over-engineering ensures that our amplifiers perform consistently and reliably in harsh, heat-prone environments.

Conclusion

Our design philosophy is simple: build amplifiers that deliver reliable, clean, and powerful audio. We prioritize performance and longevity by carefully selecting components, optimizing power delivery, and managing heat effectively. The result is an amplifier that works as intended, without compromise, across a wide range of operating conditions.

Manufacturing Process

Our manufacturing process is designed to translate our engineering principles into tangible, high-performance products. Our focus is on component quality, precise assembly, and rigorous quality control at every stage.

1. Component Sourcing

- To ensure high-quality components, we source them from reputable suppliers like Mouser, DigiKey, Element14, or directly from the component manufacturers.

- All incoming components undergo a virtual inspection to identify physical dents or other damage incurred during transit. Only components meeting our stringent standards proceed to our inventory.

- At this stage, key components are subjected to tolerance level testing

2. PCB Assembly Process

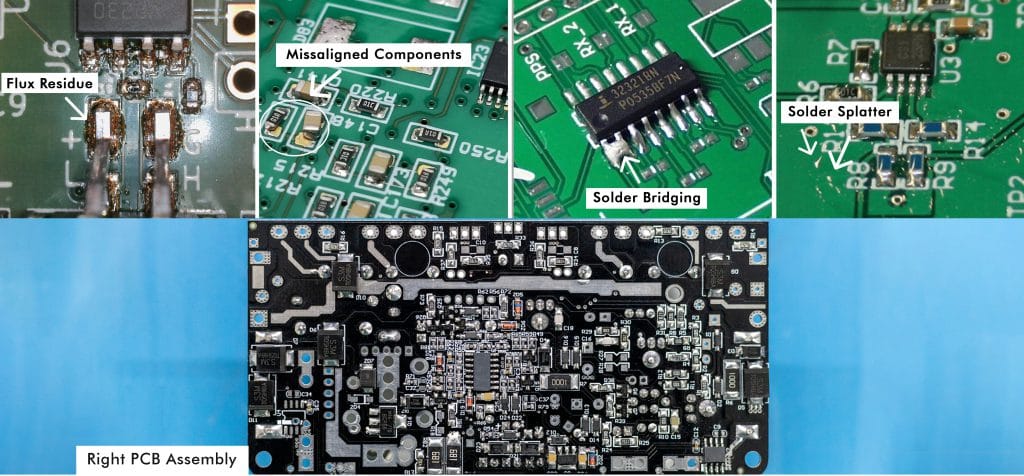

- The placing and soldering of the parts onto the blank circuit board, or the PCB assembly process has a major impact on the performance of the final product.

- Each of the assembled PCBs undergoes a 6-step check

- To prevent micro-cracking, strict control over the moisture levels of the electronic parts and materials is monitored during the assembly process.

- All contaminants are removed from the circuit board with a cleaning process. This helps ensure long-term reliability.

- The surface-mounted parts are placed carefully ensuring correct part placement and polarity.

- Following soldering, the PCB assembly is thoroughly cleaned to eliminate flux residue that can compromise performance.

- The assembly is then inspected to verify the correct part placement and orientation on the final PCB assembly.

- A preliminary Quality Assurance and Quality Control (QAQC) test is conducted on every assembled PCB. This includes visual checks and power-on measurements of critical parameters such as THD+N, Signal-to-Noise Ratio, and Frequency Response. The PCBs that pass the quality check will proceed to assembly into the chassis while PCBs that do not meet our specifications are immediately rejected.

For good audio performance it is essential that the assembly is free of contaminants like flux and solder residue.

3. Product Assembly

- All the individual parts and sub-assemblies – PCBs, transformers, wire harnesses, chassis, etc – are sent to the Assembly Department to assemble the finished units.

- All our connectors are crimped and then soldered.

- To ensure all our wires are of proper gauge and type, we follow stringent SOPs.

- 100% shielded cables are used for highly sensitive areas.

- Careful attention is paid to organize the wires to avoid any crosstalk or signal degradation. Each wire joint is inspected to ensure that it is clean, secure and strain-free.

Product Testing

To ensure every product meets our stringent performance and reliability criteria, we go beyond the standard practices.

- We spare no expense and ignore conventional time constraints to ensure every product undergoes an exhaustive testing regimen.

- Each amplifier undergoes an extensive burn-in period of at least 100 to 150 hours, a process that helps identify any potential early-life failures.

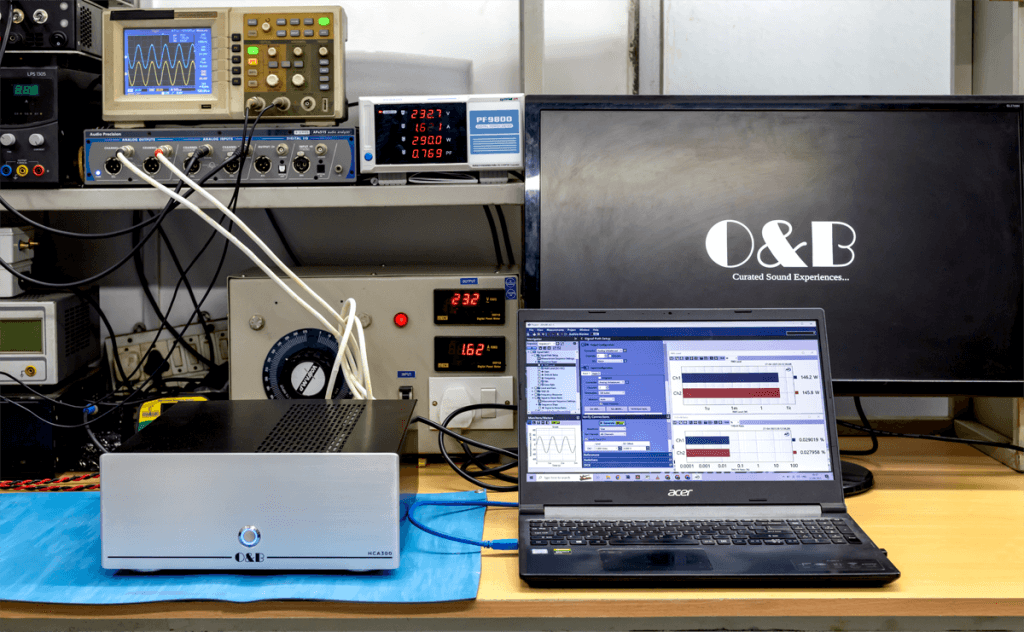

- We measure key performance parameters using the gold standard in audio testing – Audio Precision’s APX515

- Total Harmonic Distortion + Noise (THD+N)

- Signal-to-Noise Ratio (SNR)

- Crosstalk between channels

- Frequency Response across the audio spectrum

- Deviation from ideal performance

- Gain accuracy and consistency

- Our products are next subjected to rigorous thermal stress tests, simulating real-world operating conditions with progressively challenging speaker loads: 8Ω, 4Ω, 2.8Ω, 2Ω, and even 1Ω for select high-current models.

- This is then followed by a grueling 100-150 hour thermal test post which we conduct additional assessments using reactive loads, combining sine wave and music signals to push our products to their limits.